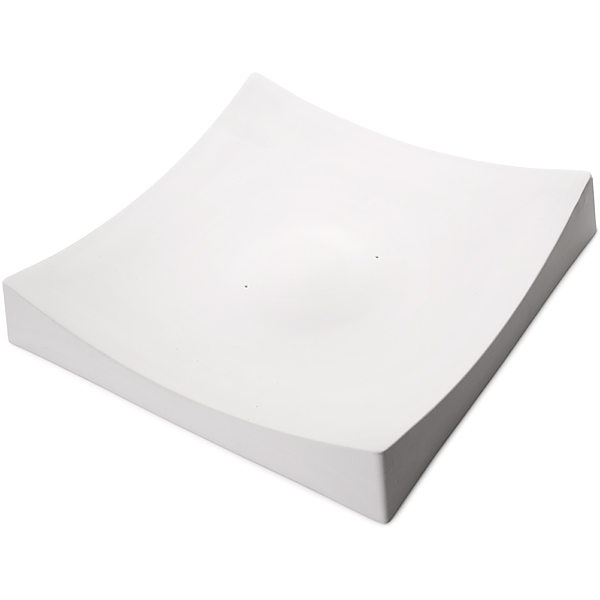

Creative Ceramics Moulds for Fusing, Slumping & Casting

This elegant template offers numerous applications from art object to lifestyle accessory, gift object and many more. The size and depth of the mould also suggests the option of dinner ware for salads, deserts etc.The mould has a small base which makes the glass object potentially unstable if used as dinnerware. To increase the size of the base, you can cut a thin layer of ceramic fibre board to fill up the most narrow par of the mould. You can cut the glass shape to match the full outline of the mould, but you can also use a smaller piece of glass or one with an uneven outline.

Recommended Firing Chart

Please Read: The steep angle of the mould may result in an uneven slumping. Reposition the slumped piece and fire a second time. Use a very low slumping temperature with a long soak.This firing recommendation has been calculated for use with Bullseye glass. Whereas the most typical casting glasses are frit and billets, you can have great results using sheet glass, stringers, rods as well as prefabricated components.The chart shown below is also based on the assumption that you are using a top fired kiln, e.g. Paragon GL22, GL24, BVD Flat bed kilns etc.Following this recommended firing chart will lead to a smooth piece of glass with a glossy surface. The finished piece will shrink somewhat, depending on the amount of glass used. Some coldworking on the edges with a diamond pad may be necessary. By lowering the temperature to a sinter firing (approx. 720°C) the piece will shrink less and have a 'sugary' look similar to pâte-de-verre.

Specific References

9987 2.300000