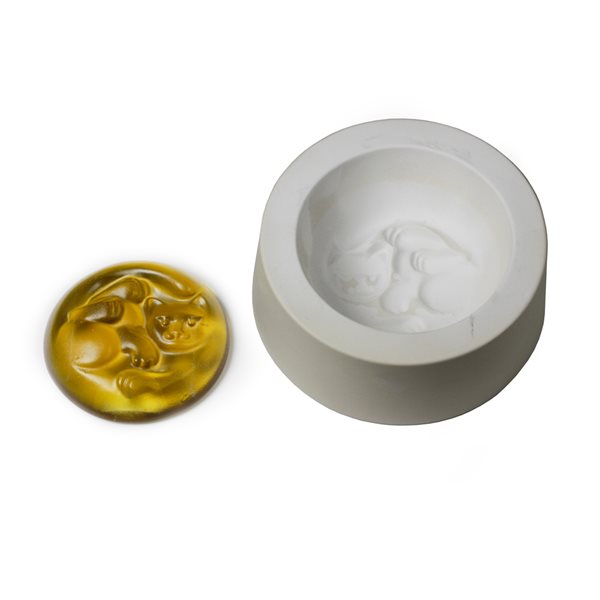

Creative Ceramics Moulds for Fusing, Slumping & Casting

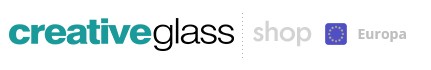

The smooth inside of this mould will give you a shiny glass surface with hardly any need for coldworking. Coldworking of one side is an option to reveal the inside life of the pyramid. You can vary the glass quantity to alter the size of the final piece. For a full pyramid you need approx. 2 kg of glass. For high clarity use billets but you can also use sheet glass, frit or rods for different results.

The recommended firing chart will lead to a smooth piece of glass with a glossy surface. The finished piece will shrink somewhat, depending on the amount of glass used. Some coldworking on the edges with a diamond pad may be necessary.

By lowering the temperature to a sinter firing (approx. 720°C) the piece will shrink less and have a rougher ‘Sugary’ look similar to pâte-de-verre.

By lowering the temperature to a sinter firing (approx. 720°C) the piece will shrink less and have a rougher ‘Sugary’ look similar to pâte-de-verre.

Recommended Firing Chart

Please Read: This firing recommendation has been calculated for use with Bullseye glass. Whereas the most typical casting glasses are frit and billets, you can have great results using sheet glass, stringers, rods as well as prefabricated components. The chart shown below is also based on the assumption that you are using a top fired kiln, e.g. Paragon GL22, GL24, BVD Flat bed kilns etc.

Specific References

9270 1.980000